intelligent equipment

With complete mechanical design, electrical design, software development and precision manufacturing capabilities, we can provide overall solutions for smart factories according to customer requirements. The products include data acquisition and monitoring system, multi-station automation intelligent equipment, comprehensive performance testing equipment, intelligent logistics warehousing system, etc.

Innovation & Application Lab of Intelligent Manufacturing

It aims to focus on the major strategic needs of the company's digital transformation and development, take the new generation of information technology such as 5G, edge computing, cloud platform and AI intelligence and the deep integration with the traditional manufacturing industry. According to the needs, the production information system such as MES, WMS and SCADA is taken as the control center, and the intelligent equipment is taken as the carrier. We will make overall plans for intelligent

Intelligent Stereoscopic Warehouse

Through the application of intelligent technology such as intelligent scanning code sensing, automatic palletizer control, conveying movement algorithm and data analysis, WFIE has the design and manufacturing capabilities of shelf planning, design and manufacturing of stackers less than 200kg, intelligent silo control system, conveyor &AGV port integration and control, etc. Products cover single column single roadway, single column double roadway, single column double roadway double deep positio

Multifunctional Test Bench

By scanning product models, automatic access to test procedures, according to the pre-defined requirements of the test conditions, automatic monitoring and recording system related flow, rail pressure, temperature, negative pressure and other important data, to achieve a comprehensive integration of product running-in and performance test automatic switch, test results and pump serial number binding, to ensure the traceability of data. The test bench has the characteristics of fast clamping, hig

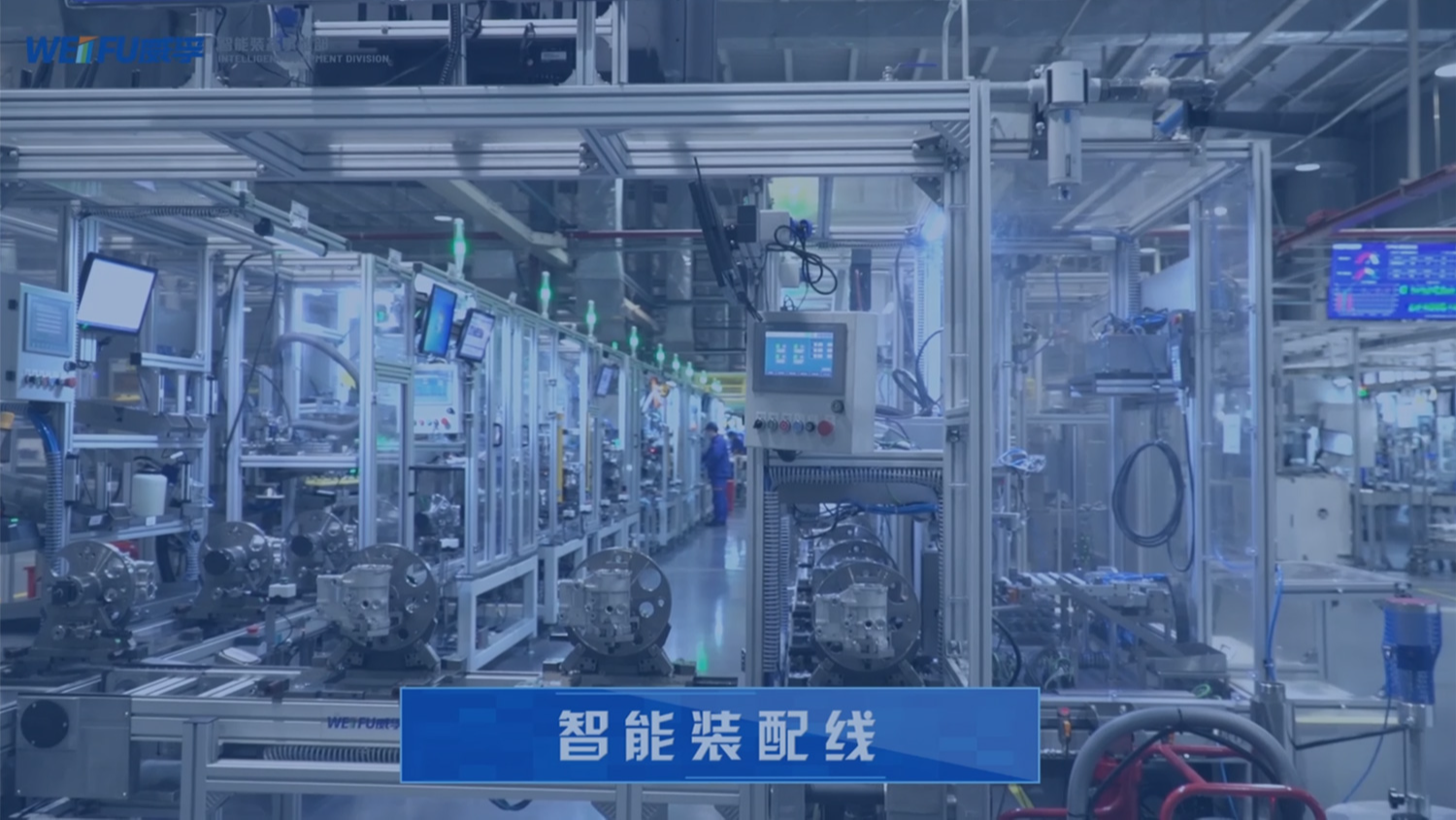

Intelligent Assembly Line

Combined with lean production concept of process planning and standard, modular patent units, set design, manufacturing, application in one of the software/hardware capabilities, we can provide intelligent iot solutions for assembly automation according to customer requirements. Through the comprehensive application of RFID, robot, vision system, SCAD, ESOP electronic Kanban and other technologies and hardware, it can integrate the assembly line conveying system, automatic feeding system, automa

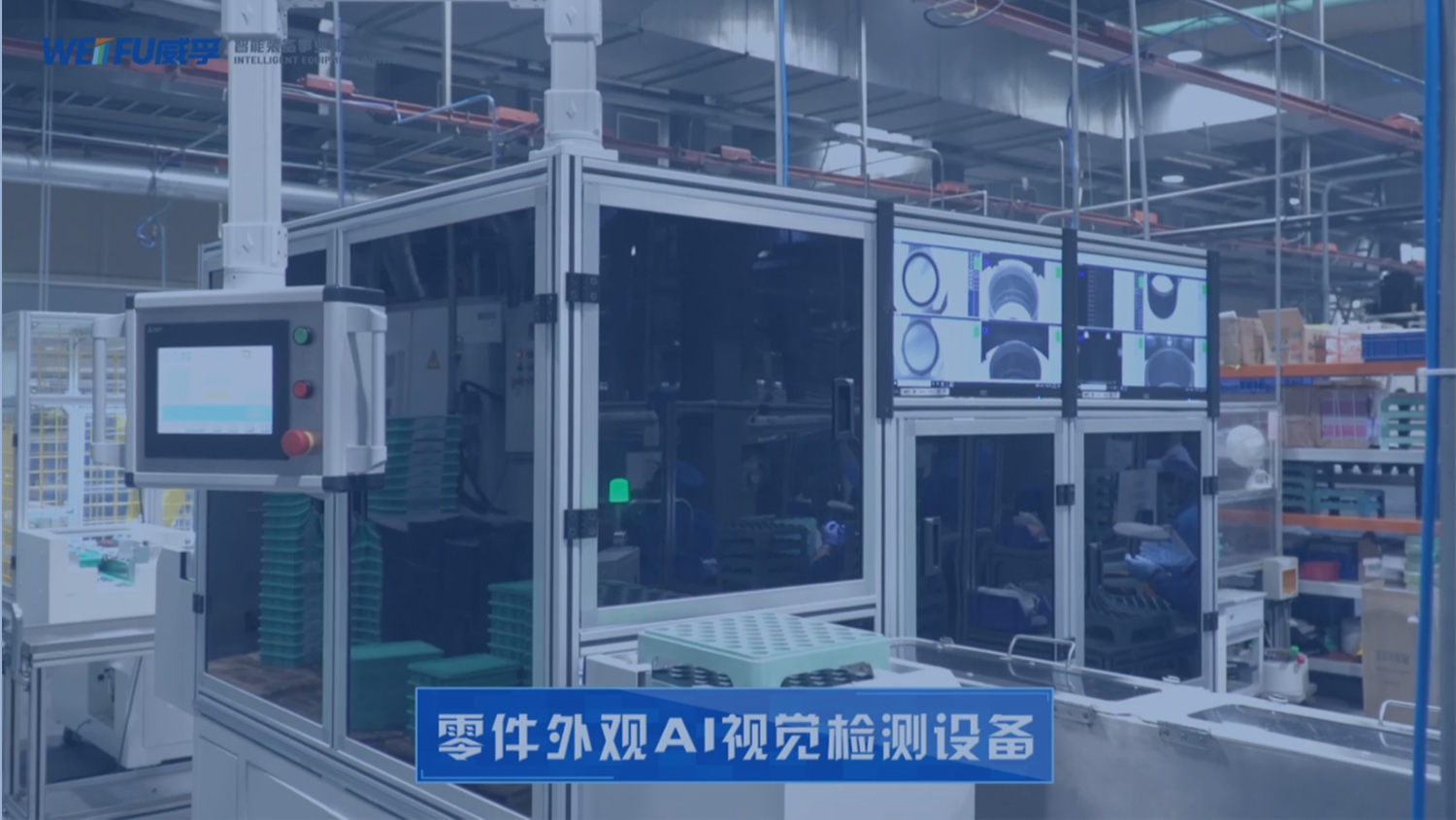

AI Visual Inspection Equipment

Different cameras, lenses and light sources are selected to detect different appearance defect patterns through AI vision deep learning algorithm, such as poor phosphating, rust spots, bruises, holes burr, pinch marks, cracks, etc. At present, it is equipped with a combination of cameras of Cognex, Hikvision, Keenes and other brands, 4 kinds of industrial lenses and 62 kinds of light sources to meet various detection needs.

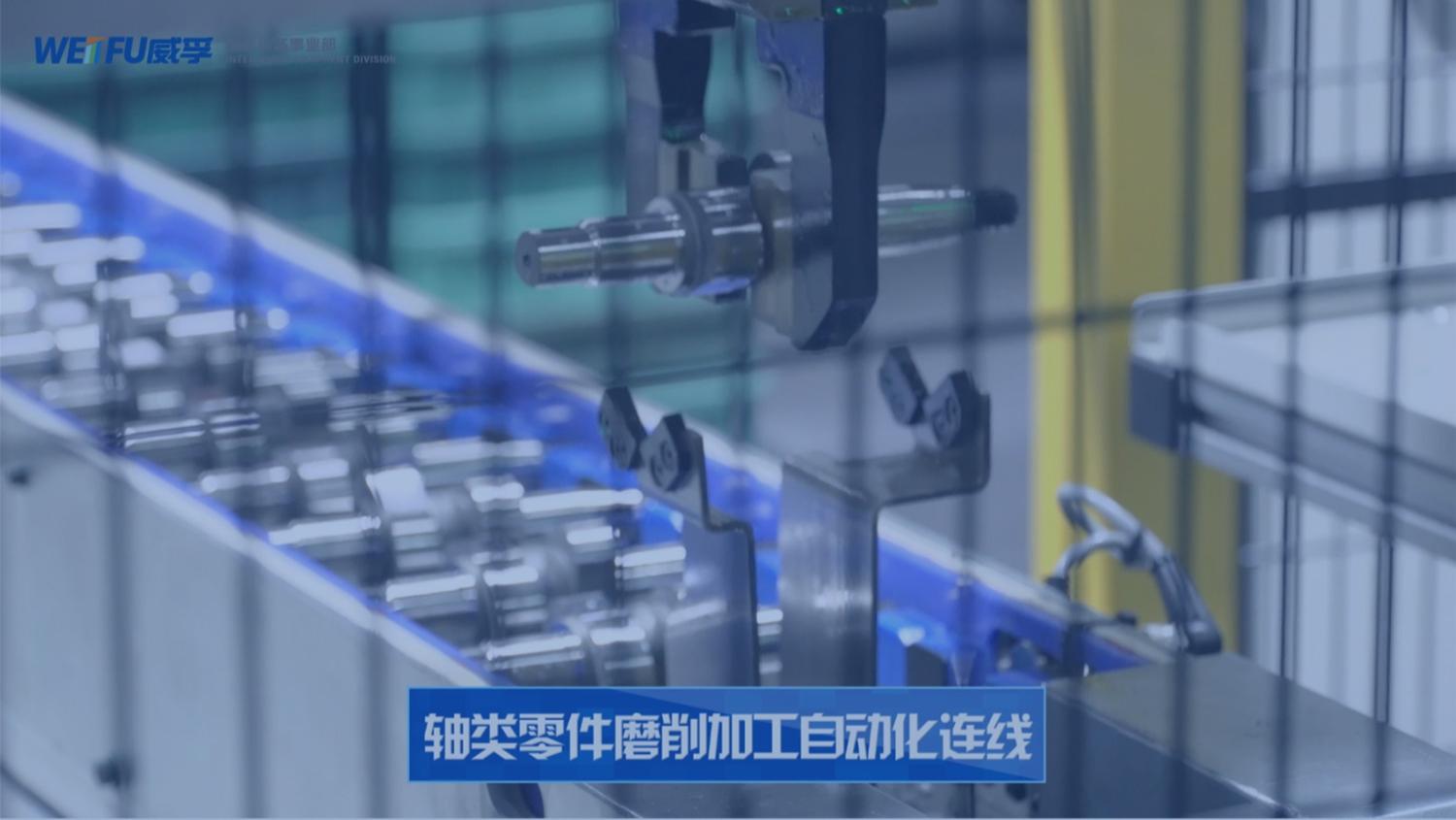

Automated Production Line

After the automatic transformation, the trusses and the double-station grips of the manipulator are adopted to realize the automatic loading and unloading of the production line. At the same time, through the establishment of CNC SCADA platform and FDC data collection platform, the goal of product flow data collection, quality information tracing and production system monitoring are realized. SCADA is a data acquisition and monitoring control system independently developed by Weifu. Through the